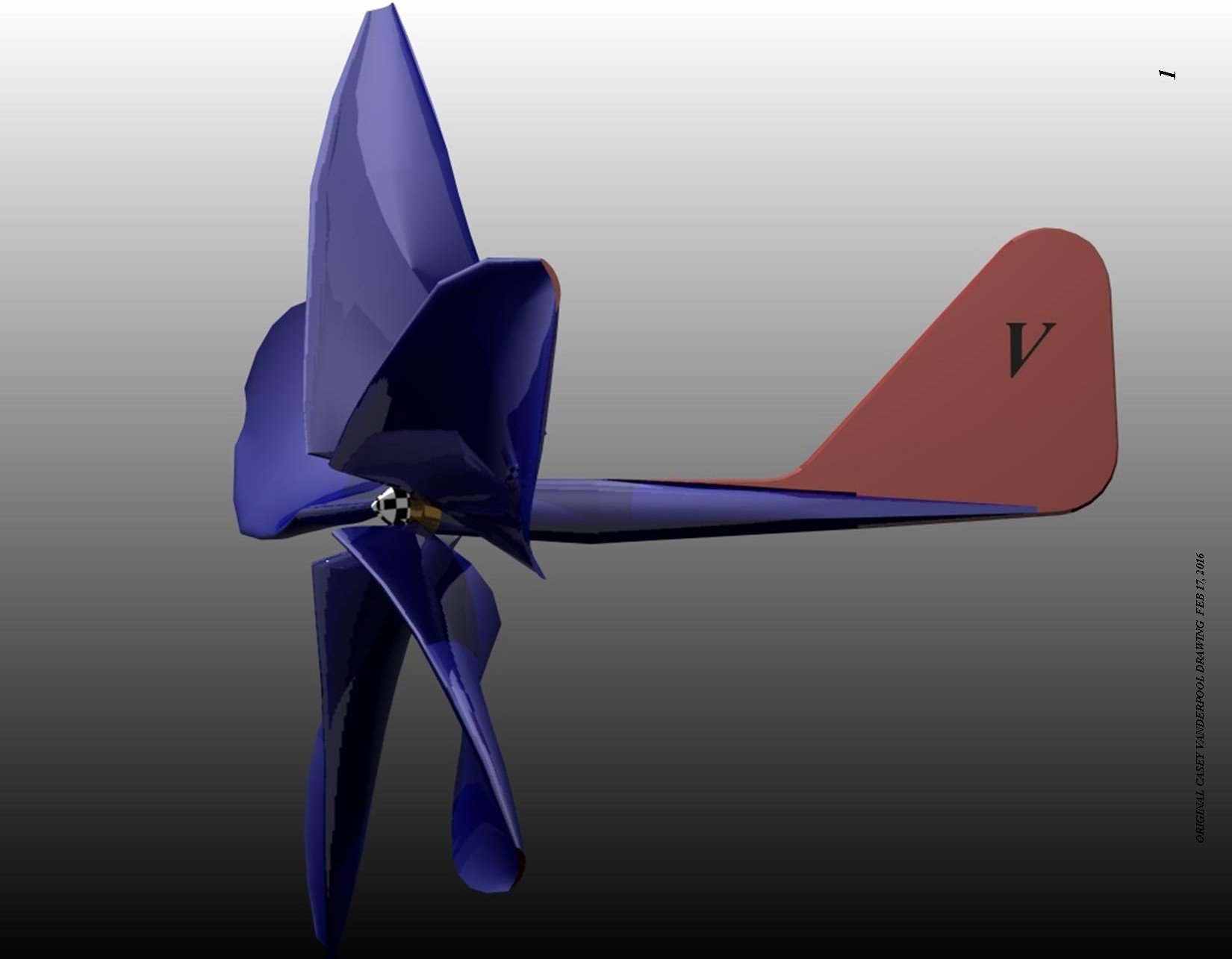

THE VANDERPOOL V-SERIES WIND TURBINE

TECHNICAL DESCRIPTION

The V-Series are two, three, four or five blade, twelve-foot diameter low aspect ratio wind turbines developed with the principles of aviation. Primary consideration was given to the airfoil and surface area requirements for low wind velocities. The blades are twisted in accordance with time tested airscrew theory, ensuring proper angle of incidence taking into account rotation velocity differentials and resultant force vectors. Rotational energy is imparted to the blades by ambient wind, spinning more than several possible low cost generator combinations. The dimensions and profile are designed to maximize torque applied to an alternator or generator, thus, electrical charge to rechargeable batteries, and power for heating, cooling, pumping or any function where continuous low amp circuits or intermittent high energy systems are connected. Further, the design of the system is such that the blades can be gently slowed to a halt, and if necessary, removed from the hub for any reason without difficulty. Hand braking is achieved by rotating a drive handle ball located inside the main body accessible from underneath the core apparatus, which actuates contact between friction plates and a brake disc. Removal of the Blades is achieved via one quarter turn locking knob at the end of each hub radial. Over speed protection is accomplished automatically by the pitch change mechanism of the cam and spring of the blade spar tube riding on the roller bearing guides of the radial hub and operating against and in proportion to the centrifugal forces of rotational speed. Thus, the same forces which tend to over speed the turbine are manipulated to act as a regulator and governing braking force without mechanical friction. The main body along with the rotating turbine blades can rotate three hundred and sixty degrees upon its mast automatically aligning itself with local wind direction by aerodynamic forces acting on its tail. The mast head dynamic force loads are carried through twin ball bearings supporting the main crankshaft and a dual ball bearing mast seat assembly. Transmission of electrical continuity through the mast seat to the wiring below is accomplished via a slip ring contacts plug. Standard construction emphasis is on low cost composite poly-matrix, and mild flat and tubing steel as the materials of choice allowing for ease of fabrication, smooth, weather proof and paint ready surfaces. The system is large enough to provide large amounts of energy, yet small enough to be installed on most kinds of homes and building structures in most locations. The great advantage of the V-Turbo is the cultivation of electricity out of thin air by the fusion of aerodynamic principles and simple construction making this machine lightweight, versatile, affordable and reliable.

Contact Us

Interested in working together? Fill out some info and we will be in touch shortly. We can’t wait to hear from you!